Understanding the Open Type Diesel Generator Set Design

What defines an open type diesel generator set?

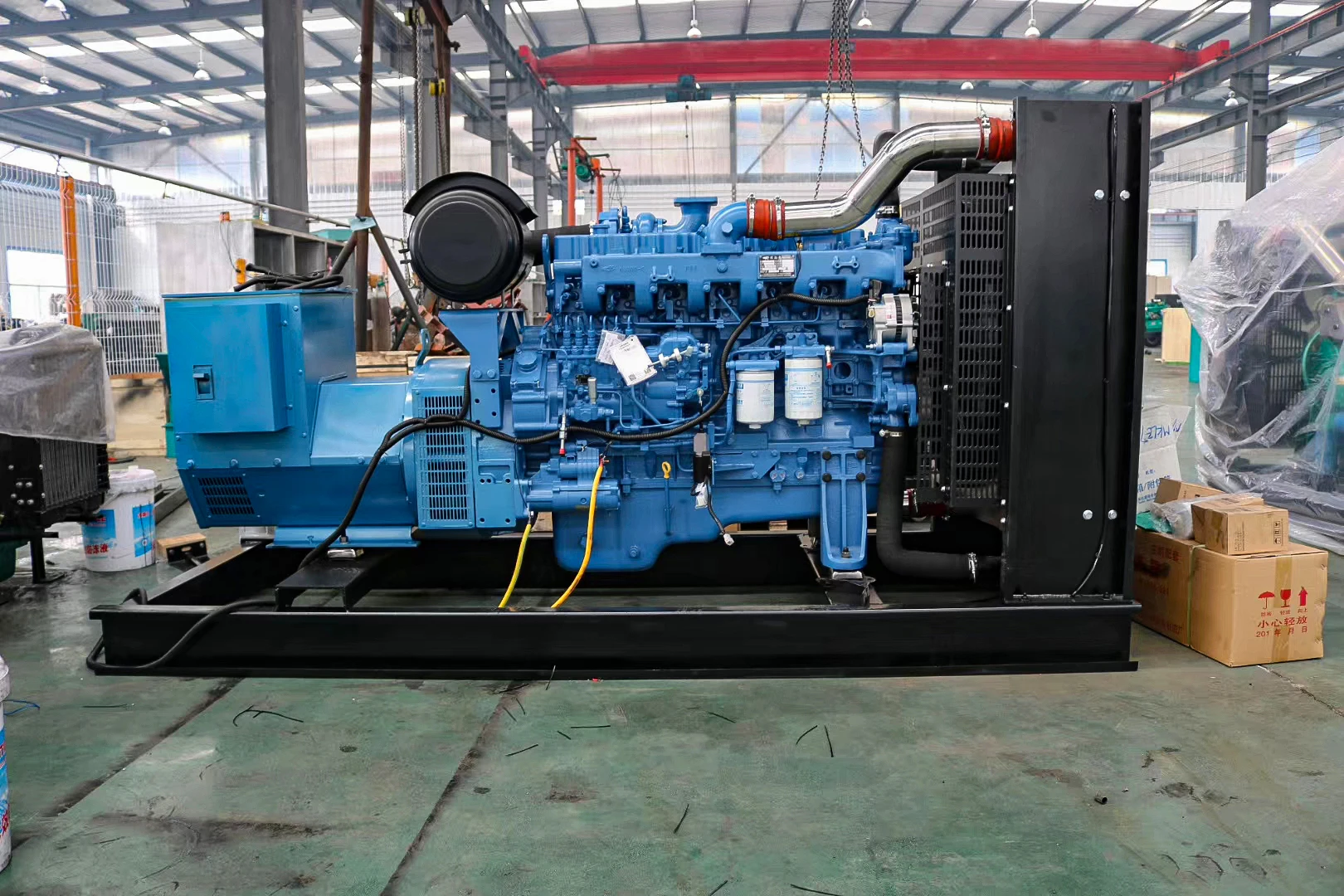

Open type diesel generator sets feature an open-frame design without protective enclosures, prioritizing direct component accessibility. This configuration exposes critical elements like the diesel engine, alternator, and control systems, streamlining maintenance workflows. Unlike enclosed models, the absence of sound-dampening panels or weatherproof housings simplifies physical access to internal mechanisms.

Key components and accessibility in open frame models

The main parts like engine blocks, cooling systems, fuel injectors and electrical controls are all placed where they can be reached quickly. When these components are visible, it cuts down on the hassle of taking things apart for regular inspections. Technicians simply look at belts, check filters and examine wiring without having to remove any protective housing first. According to recent field data from maintenance crews, jobs that involve changing fluids or swapping out parts generally finish about 28 percent faster than with those closed-up systems. The Industrial Energy Journal published similar findings back in 2023, reinforcing what many hands-on workers have noticed firsthand over the years.

Comparison with soundproof and containerized units

| Feature | Open Type Units | Soundproof/Containerized Units |

|---|---|---|

| Component Access | Immediate | Requires panel removal |

| Noise Reduction | Limited (75–85 dB) | Enhanced (60–70 dB) |

| Weather Protection | Minimal | Full enclosure |

While soundproof models excel in noise-sensitive environments, their layered enclosures add 15–20 minutes to repair workflows. Containerized units provide weather resilience but limit on-site adjustments due to fixed configurations. Open type designs dominate applications where rapid servicing outweighs environmental mitigation needs.

Why Maintenance Simplicity Makes Open Type Diesel Generator Sets Popular

Market Perception of Maintenance Ease for Open Type Diesel Generator Sets

Looking at how different industries are adopting equipment, there seems to be a clear trend toward open type diesel generators, especially in fields where getting quick access for maintenance really matters. We're talking about places like construction sites and mines where downtime costs money. These open designs don't have all those complicated access panels or separate compartments that come standard with enclosed units. Just take a look at what happened according to a recent industry poll from 2023. Around two thirds of facility managers surveyed said they prefer these open frame models when setting up operations in remote locations. Makes sense too since problems can be spotted and fixed much faster without having to tear apart layers of protective casing first.

Field Reports on Reduced Service Time Due to Exposed Components

Looking at maintenance records across twelve mining operations in Australia reveals something interesting: technicians can finish their regular service checks about thirty percent quicker with open type units compared to those pesky enclosed generators. What makes this possible? Well, these open designs give workers direct access to all the key areas at once – think alternator, fuel system, cooling stuff – which is super handy when it comes time to swap out those parts that just naturally wear down over time, like air filters that need changing roughly every five hundred to one thousand hours of operation. A company specializing in power solutions actually saved around eighteen grand each year after making the switch to these open frame models. They pointed specifically to reduced dismantling requirements as the main reason behind those cost savings.

User Survey Data: 78% Report Faster Access During Servicing

Operator surveys confirm real-world efficiency gains:

- 78% of technicians replace fuel injectors in Ω€90 minutes, versus 2.5 hours on enclosed units

- 92% rate component visibility as "excellent," compared to 43% for soundproofed models

- 61% fewer tool or part misplacement incidents due to uncluttered workspaces

This advantage is crucial in harsh environments, where each minute of downtime costs an average of $2,300 in industrial operations (Energy Council Report, 2022).

Core Preventive Maintenance Practices for Open Type Diesel Generator Sets

Routine inspection as the foundation of generator reliability

Regular checkups really matter for open type diesel generators since they get exposed to all sorts of dirt and grime from the environment. Most technicians suggest doing weekly looks at fuel lines, checking coolant levels, and inspecting electrical connections. Throw in some monthly load bank tests too. These simple steps help catch problems before they become big headaches. Companies that keep track of their maintenance schedules tend to see around 40% fewer unexpected breakdowns than those waiting until something goes wrong. The difference between planned maintenance and fixing things after a failure can save thousands in repair costs and lost productivity over time.

Fluid and filter changes in open type diesel generator sets

The open-frame design simplifies oil and filter replacements, which should occur every 500 operating hours. Delayed changes increase particulate contamination by up to 30%, accelerating engine wear. Using manufacturer-approved fluids ensures warranty compliance and prevents viscosity-related issues that compromise lubrication efficiency.

Cleaning and lubrication: Preventing failures through upkeep

Dust buildup on radiators and alternators impairs heat dissipation. A 2023 Thermal Management Study found quarterly compressed air cleaning of cooling fins improves thermal performance by 22%. Bearings and other rotating components require grease lubrication every 1,000 hours; neglected joints contribute to 17% of premature diesel generator failures.

Fuel system maintenance and addressing fuel quality issues

Fuel contamination accounts for 34% of open type diesel generator failures (Power Systems Journal 2022). Best practices include monthly testing for water and microbial growth, along with biannual tank sludge removal. Installing secondary fuel filters helps protect injection systems from abrasive particles common in industrial settings.

Regular exercise of diesel generators to maintain system health

To prevent wet stacking, unused open type units should undergo bi-weekly 30-minute no-load runs. According to the North American Reliability Corporation (NERC), adherence to this protocol reduces startup failures by 45%. These exercises circulate lubricants, maintain battery charge, and validate automatic transfer switch operation.

Real-World Efficiency: Case Study from an Australian Mining Operation

Open Type Diesel Generator Sets in Harsh Industrial Environments

At a mine operation in Western Australia, open type diesel generators proved their worth in some seriously tough conditions. Temperatures regularly hit 48 degrees Celsius there, plus the air was thick with dust from constant drilling activity. Enclosed generator models would have struggled badly in this environment because they can't get enough airflow. But these open designs stayed cool even after running nonstop for 18 hours straight. Being able to see all the parts clearly made troubleshooting much faster for the maintenance crew. That meant the power kept flowing to the drills and processing equipment without any interruptions, which is absolutely critical in such remote locations where downtime costs money fast.

Maintenance Records Show 30% Fewer Downtime Hours

2023 maintenance data revealed open frame units experienced 30% less downtime than previously used containerized models. Average service intervals dropped from 14 to 9.7 hours, primarily due to eliminated panel-removal tasks—which historically consumed 41% of maintenance time in enclosed systems (Industrial Power Report 2023).

Technician Feedback on Repair Speed and Component Replacement

Around 87 percent of maintenance teams found that open type units really cut down repair times, particularly when dealing with those pesky alternator brush replacements and checking out turbochargers. One shop foreman mentioned that changing cylinder head gaskets took about 25% less time since there was no need to take apart the whole enclosure. But wait, there's another side to this coin. About two thirds of the crew actually suggested better weatherproofing for those electrical connections, especially at coastal installations where salt air is constantly eating away at components. They pointed out that extra protection against corrosion would be pretty important in these kinds of salty environments.

The Future of Maintenance: IoT and Predictive Programs for Open Type Units

Digital Logs and Structured Maintenance Tracking

The shift for open type diesel generators away from those old paper records toward digital management systems is happening fast. These new digital platforms let techs spot wear issues around 80 percent quicker compared to flipping through binders and handwritten notes, according to recent industry research from last year. What makes these cloud connected systems so valuable? They keep everyone on the same page when it comes to diagnostics no matter where they're located. Teams can check real time data without waiting for someone else to update spreadsheets, which cuts down mistakes and keeps operations running smoother overall.

Integration of IoT Sensors in Modern Open Type Diesel Generator Sets

IoT technology enhances maintenance through embedded sensors monitoring vibration, temperature, and pressure. The exposed structure of open frame units simplifies sensor installation, enabling continuous monitoring of alternator bearings and fuel injectors. Data from over 120 industrial sites shows IoT-equipped generators detect lubrication anomalies up to 48 hours before catastrophic failure.

Industry Shift from Reactive to Predictive Maintenance Strategies

Leading operators now use predictive programs that analyze historical and real-time data to anticipate maintenance needs. Facilities applying these strategies with open type diesel generator sets report:

- 55% fewer unplanned outages

- 33% lower annual servicing costs

- 27% extended component lifespans

By leveraging machine learning to replace fixed schedules with condition-based alerts, these programs optimize uptime and resource allocation. As predictive algorithms become more accessible, 72% of surveyed technicians express greater confidence in preventing failures before they occur.

FAQ

What is an open type diesel generator set?

An open type diesel generator set is a power generation unit with an open-frame design that allows for direct component access without protective enclosures, facilitating easier maintenance and servicing.

What are the benefits of using an open type diesel generator set?

The open design allows for immediate component access, reducing maintenance and repair times. It is especially useful in environments where quick servicing is a priority, such as construction sites and mining operations.

How do open type diesel generators compare to soundproof or containerized units?

Open type units allow for immediate access to components but offer limited noise reduction and weather protection compared to soundproof and containerized models, which have enclosures that add repair time but provide superior noise reduction and weather resilience.

What preventative maintenance is recommended for open type diesel generator sets?

Routine inspections, regular fluid and filter changes, cleaning and lubrication of components, fuel system maintenance, and regular exercise tests are recommended to maintain generator reliability and efficiency.

Table of Contents

- Understanding the Open Type Diesel Generator Set Design

- Why Maintenance Simplicity Makes Open Type Diesel Generator Sets Popular

-

Core Preventive Maintenance Practices for Open Type Diesel Generator Sets

- Routine inspection as the foundation of generator reliability

- Fluid and filter changes in open type diesel generator sets

- Cleaning and lubrication: Preventing failures through upkeep

- Fuel system maintenance and addressing fuel quality issues

- Regular exercise of diesel generators to maintain system health

- Real-World Efficiency: Case Study from an Australian Mining Operation

- The Future of Maintenance: IoT and Predictive Programs for Open Type Units