Definition and Core Components of an Open Type Diesel Generator Set

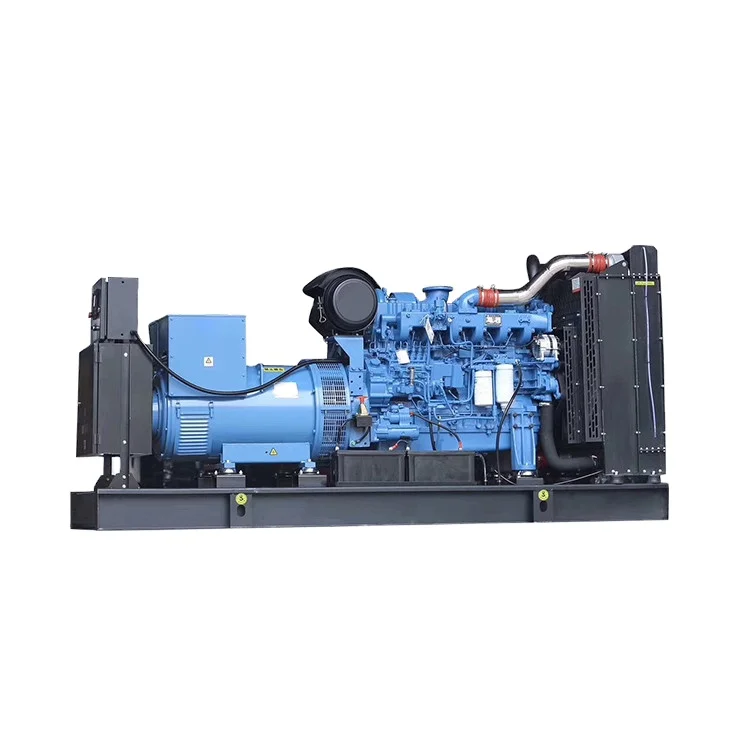

Open type diesel generators are basically big power systems made up of three main parts: the diesel engine itself, an alternator, plus a control panel. These models don't come with those soundproof boxes that enclosed units have, instead focusing on being tough as nails and easy to work on when something breaks down. Here's how it works: the engine burns diesel to create mechanical power, then the alternator turns that into actual electricity we can use. Meanwhile, the control panel keeps track of everything from voltage levels to overall system health. Built to handle rough conditions, these generators have parts that snap together quickly, making repairs much faster than other types. This matters a lot at places like construction zones where every minute without power means money lost. According to Ponemon Institute research from last year, downtime there typically costs around fifteen thousand dollars each hour.

Key Differences Between Open-Frame and Enclosed Gensets

When it comes to budget and cooling, open type units really stand out. They typically cost around 25 to 30 percent less than their enclosed counterparts right off the bat. The fact that these units are not enclosed means air can flow through them much better, which helps prevent those annoying overheating issues when running at full capacity for long periods. On the downside though, they tend to be pretty loud, usually hitting between 85 and 95 decibels. That makes them less ideal for city environments where neighbors might complain about the noise. Another advantage worth mentioning is how much quicker technicians can get to components inside open frame generators. This accessibility cuts down on maintenance time by roughly 40%, something plant managers appreciate when downtime translates directly into lost revenue.

Typical Power Range and Performance Metrics

Open type diesel generator sets generally range from around 20kVA all the way up to 2000kVA, though it's the 100 to 500kVA units that see most action across factories and warehouses. The better quality models can handle about 80% of their maximum output continuously for over twelve hours straight. When everything runs smoothly, these machines manage fuel consumption rates between 0.3 and 0.5 liters per kilowatt hour. Industry pros often suggest going with a generator sized at least 25% larger than what's actually needed for day to day operations. This extra capacity isn't just padding; field tests have shown this approach actually increases engine longevity by roughly a fifth according to recent industry reports.

Top Advantages of Open Type Diesel Generator Sets for Industrial Use

Rugged Design for Harsh and Remote Environments

The open frame design of diesel generators makes them tough enough to handle some pretty harsh environments. These units come with heavy duty steel construction and materials that stand up to the elements, so they work reliably even when deployed in places like desert oil fields, underground mines, or along saltwater coastlines where regular equipment would fail fast. Because parts are accessible without dismantling everything, maintenance crews can easily clear out dust buildup and check components for wear before problems develop. That accessibility really matters in locations where humidity eats away at metal surfaces over time. The fact that these generators last longer between breakdowns is huge for industries where production schedules cannot afford unexpected stoppages, especially in remote operations where getting replacement parts takes days instead of hours.

High Power Output and Load Handling Capability

These generators deliver consistent power outputs exceeding 500 kVA, making them ideal for heavy industrial equipment like crushers, cranes, and welding systems. Open-type units efficiently manage abrupt load spikes (up to 110% of rated capacity) without voltage fluctuations, ensuring uninterrupted workflows. Their direct air-cooling systems prevent overheating during prolonged high-demand operations.

Fuel Efficiency and Lower Operating Costs

The reason diesel fuel works so well in open type generators is because of its much higher energy content. These units typically get about 25 to 30 percent better mileage than their gas powered counterparts. When manufacturers optimize the combustion process, generators rated below 200 kVA will burn no more than 210 grams per kilowatt hour. That means less frequent refills which cuts down on those expensive logistics headaches at remote locations. For factories running non stop operations, this kind of efficiency can save anywhere from eight thousand to twelve thousand dollars each year according to a recent study published in Energy Economics Review back in 2023.

Enhanced Cooling and Simplified Maintenance Access

The open-frame design maximizes airflow, allowing 40% faster heat dissipation than enclosed units. Technicians can access filters, injectors, and belts without disassembling panels—cutting routine maintenance time by 50%. This accessibility is particularly valuable in regions with limited availability of skilled labor.

Common Applications Where Open Type Gensets Excel

Construction Sites and Temporary Power Setups

For construction sites needing portable power sources, open type diesel generators stand out as incredibly versatile options. The modular nature means they can be deployed fast to run everything from big excavators to those bright orange lighting towers workers love so much, even when the ground isn't exactly flat. According to some recent research from Power Systems Research back in 2023, around 78 percent of contractors actually favor these open frame units for temporary jobs. Why? Well, they set up in under two days most of the time, and save about 20% on fuel costs compared to their enclosed counterparts doing similar workloads. What really matters though is how tough these machines are. They handle all sorts of harsh conditions without blinking an eye dust storms sweeping through, extreme heat or cold changes throughout the day, plus constant vibrations from nearby construction activities.

Remote Mining and Infrastructure Projects

Off grid mining operations typically depend on open frame diesel generators to supply reliable power ranging from 500 to 3000 kVA for things like drilling equipment, processing plants, and worker camps. The open design helps these machines stay cool even when running non stop in those sweltering underground environments where temperatures can get really intense. These generators work well in remote areas because they can run for days at a time between fuel stops, sometimes as long as 72 to 120 hours. Plus, they handle lower quality diesel fuel which is often what's available far from main roads. According to the Global Mining Review report last year, this setup cuts down how often crews need to bring in fresh fuel by around 37%, making life much easier for maintenance teams working in isolated locations.

Emergency and Backup Power in Urban Development

Cities often turn to open frame generators when dealing with power grid improvements or after major storms hit. The design makes it easier for technicians to access parts quickly even in tight city spaces, which means getting things back online happens about 53 percent faster according to a recent report from Urban Power Solutions. Of course, in neighborhoods where people live close together, these machines need protective covers against rain and wind. Still, they provide essential backup power ranging from 200 to 1500 kilovolt amperes for places like hospitals keeping life support running, traffic lights staying green, and tall buildings maintaining elevator service. Most importantly, modern versions come equipped with special filters that clean up emissions and panels that reduce noise levels, helping meet environmental standards while still responding to urgent situations.

Environmental and Operational Challenges to Consider

Noise Levels and Site Compliance Requirements

Open type diesel generator sets typically operate at 75–85 dB(A), requiring strategic placement to meet OSHA workplace noise limits and local ordinances. In urban areas, construction sites often implement sound barriers or schedule high-load operations during daytime hours to comply with 65 dB(A) residential zone limits.

Weather Exposure and Protective Installation Strategies

Without enclosures, these gensets need weatherproof canopies or purpose-built shelters in coastal or desert environments. A 2022 Arctic drilling project reduced corrosion-related downtime by 40% using heated enclosures and triple-layer air filtration—demonstrating how site-specific protection extends service life.

Emissions and Urban Use: Balancing Power Needs with Regulations

EPA Tier 4-compliant models reduce particulate matter by 90% compared to older units, yet urban projects still face strict NOx emission caps (0.30 g/kWh in California). Hybrid systems combining solar arrays with diesel generators help construction firms cut runtime by 35% while meeting city air quality standards.

How to Choose the Right Open Type Diesel Generator Set for Your Needs

Selecting an open type diesel generator set requires balancing power demands, site conditions, and operational priorities. Over 40% of industrial energy waste stems from mismatched generator sizing (Diesel Power International 2023), making systematic evaluation critical for cost-effective operations.

Assessing Power Requirements and Load Profiles

Start by calculating your peak and average load demands using historical data or predictive modeling. Open type units typically deliver 25—3,500 kVA outputs, but oversizing by just 15% increases fuel consumption by 8—12% (Energy Logistics Report 2022). Analyze load types—resistive, inductive, or hybrid—as motor-driven equipment may require 300% surge capacity during startup.

Portability, Installation, and Site Logistics

Prioritize trailer-mounted configurations for projects requiring frequent relocation, though permanent installations in coastal areas demand corrosion-resistant coatings. Ensure a 1.5m clearance radius around the generator for airflow and maintenance access. For remote sites, confirm local fuel storage complies with NFPA 110 standards for diesel containment.

Matching Specifications to Application Demands

| Application | Key Specifications | Critical Factor |

|---|---|---|

| Construction Sites | 100—500 kVA, trailer-mounted | 85—95 dBA noise tolerance |

| Urban Backup Power | <75 dBA noise rating, UL2200 compliance | Emissions meeting EPA Tier 4 |

| Mining Operations | 800—2,000 kVA, dust-proof filters | 50°C ambient temp operation |

Verify fuel efficiency tiers—modern open type generators achieve 0.28—0.35 L/kWh consumption—and confirm emissions compliance for your region. Units designed for hospital backup should incorporate automatic transfer switches, while marine applications require SAE J1171 corrosion protection.

FAQ

What are open type diesel generator sets?

Open type diesel generator sets are large power systems that include a diesel engine, an alternator, and a control panel. Unlike enclosed models, they do not have soundproof boxes, focusing instead on durability and ease of maintenance.

How does an open type diesel generator set work?

The engine burns diesel to produce mechanical power, which the alternator then converts into electricity. The control panel monitors voltage levels and overall system health.

Why are open frame gensets preferred over enclosed units in some situations?

Open frame gensets are typically less expensive, provide better cooling, and allow quicker access for maintenance, making them ideal for harsh environments and situations where budget and repair time are critical.

What are the typical applications for open type diesel generators?

These generators are commonly used on construction sites, remote mining operations, and urban emergency backup scenarios due to their rugged design, high power output, and efficiency.

What should be considered when choosing an open type diesel generator set?

Key considerations include power requirements, load profiles, site logistics, fuel efficiency, emissions, and specific application demands.

Table of Contents

- Definition and Core Components of an Open Type Diesel Generator Set

- Key Differences Between Open-Frame and Enclosed Gensets

- Typical Power Range and Performance Metrics

- Top Advantages of Open Type Diesel Generator Sets for Industrial Use

- Common Applications Where Open Type Gensets Excel

- Environmental and Operational Challenges to Consider

- How to Choose the Right Open Type Diesel Generator Set for Your Needs

-

FAQ

- What are open type diesel generator sets?

- How does an open type diesel generator set work?

- Why are open frame gensets preferred over enclosed units in some situations?

- What are the typical applications for open type diesel generators?

- What should be considered when choosing an open type diesel generator set?